A vehicle's tires are an important pillar in terms of performance: they are in fact those which connect it to the ground. The tire is the last, but not the only, component that transmits torque and power to the asphalt. A famous tire brand has made it its slogan: “Without Mastery, Power is nothing”, and for this, tires require extremely in-depth study. MegaRide, a spin-off from the Federico II University of Naples, has been concerned since its creation with how to extract the maximum possible grip and performance from different tires.

During Formula 1 pre-season testing in Bahrain, some tire technicians used a strange gun-shaped tool on the tires just before the cars hit the track. This is the brand new instrument called VESevo. It is a “gun” that allows you to carry out non-destructive testing on tires and reveal its smallest secrets. Being also developed to study MotoGP tires, it could quickly arrive in the paddock.

First of all, we must ask ourselves why the need for such a tool arises. In vehicle dynamics, knowledge of the viscoelasticity of compounds is fundamental to modeling the mechanics of tire-asphalt contact. This makes it possible to evaluate and predict the coefficient of friction to understand the performance of the vehicle, also in terms of safety. Therefore, it offers the possibility of obtaining more information, and at the same time having it in more detail.

Tire behavior

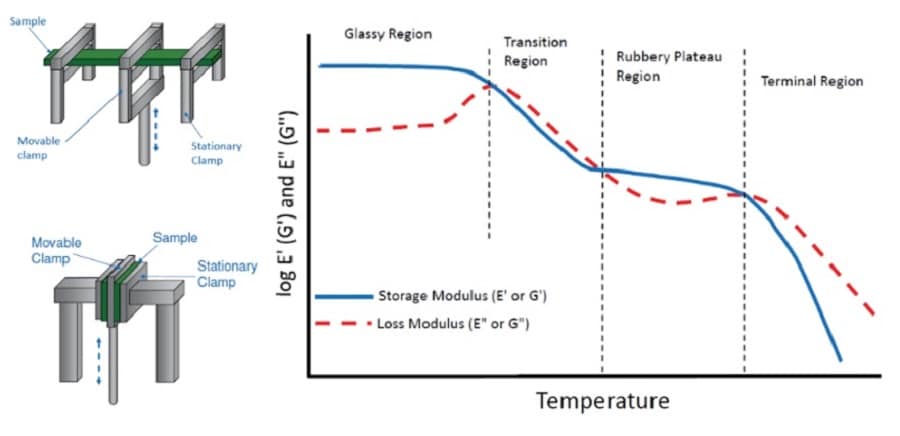

A viscoelastic material has an intermediate behavior between a purely elastic material, which respects Hooke's law, and a purely viscous material which respects Newton's law on viscosity. This means that the material under stress will deform depending on both time and temperature. The response of the hardware will be delayed, out of phase with the request. The response analysis relationship, which expresses the resistance to deformation, is a complex module consisting of the sum of two factors.

The real part, known as the storage modulus, is a measure of the elasticity of the material. It is linked to the ability to store energy during stress. The imaginary part, for its part, is called loss modulus and is linked to the ability of the compound to dissipate energy in the form of heat. The relationship between these quantities is called the loss factor. It is thanks to the latter that it is possible to analyze the dynamic applications of the vehicle. We can predict, as we said previously, the grip, but also the wear of the tire.

Viscoelastic properties are generally determined by dynamic mechanical analysis (DMA), a technique that requires quite expensive and complex laboratory instrumentation. In addition, the samples to be tested with the DMA must have precise dimensions and characteristics, and above all they must be obtained from the tire, destroying it and making it lose its functionality. Therefore, it is not possible to carry out tests on tires which will then have to be mounted on a motorcycle to send it to the track.

Example: Comparison of 3 erasers

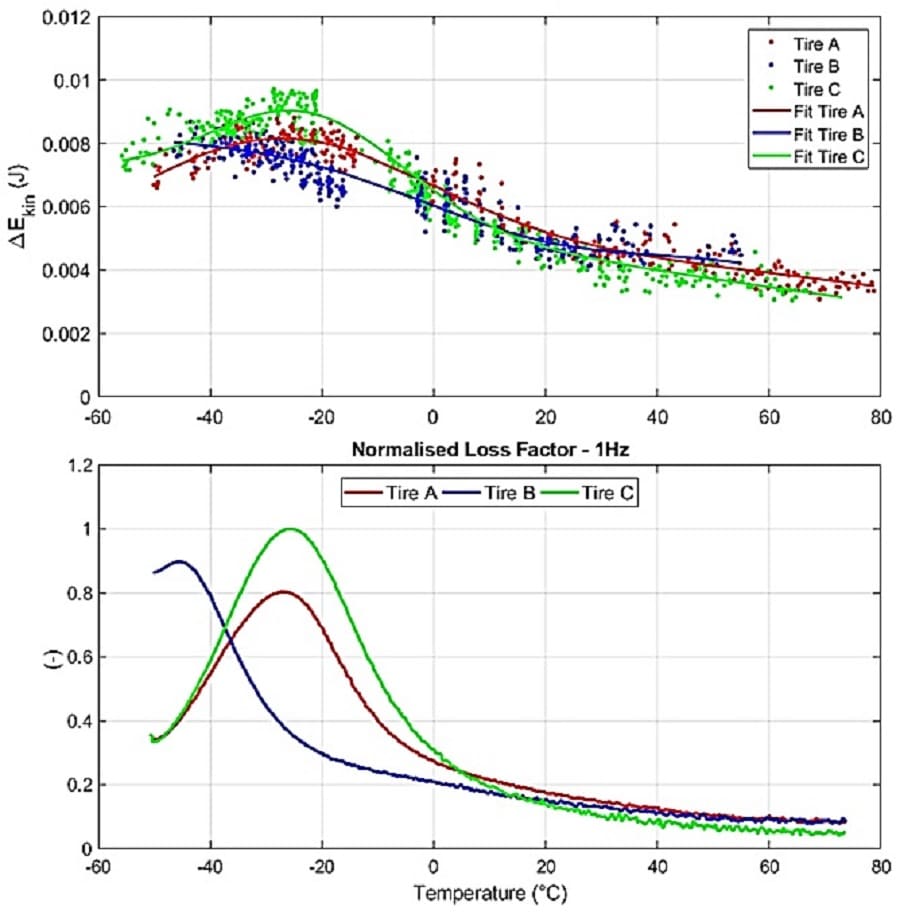

It is first necessary to define the preliminary index of viscoelastic behavior: it represents the variation of the kinetic energy before and after the first contact between the rod inside the VESevo and the tread, in a certain range of temperature. Kinetic energy is the energy possessed by a moving body and is proportional to the square of the speed.

Megaride explains that this index was chosen for this preliminary analysis for its physical consistency with the intrinsic concept of dissipation due to viscoelasticity and for its good adaptation to the available loss factor reference curves.

In the diagram above, we observe the data relating to the viscoelastic index of three reference rubbers of three tires (A, B and C) as a function of temperature, as well as their adjustment curves. The trends show a good correlation with those of the loss factor, which are normalized for trade secret in the second graph.

We observe a peak corresponding to the glass transition temperature at which the maximum energy loss occurs: on the one hand, tire C appears characterized by a higher loss factor peak than the other; on the other hand, tire B seems to have the lowest glass transition temperature, the curve being shifted to the left compared to the other two. The glass transition temperature represents the temperature below which there is glassy behavior, i.e. the movements of molecules are “frozen”, limiting everything to simple vibrations of isolated atoms, but nothing more. .

In the second part of this file, we will see how the VESevo gun makes it possible to characterize the viscoelasticity of the tire tread.